Do you know what are the safety standards for blasting operation?

Occupational Safety and Health in blasting operation:

In underground mining, open pit mining, mining, we can find that the minimum required relates to the following topics:

- physical, chemical and biological risks;

- atmospheres at risk of explosion;

- deficiencies in oxygen levels;

- ventilation;

- investigation and analysis of occupational accidents;

- any risks resulting at height, in depth and in containment areas;

- risks resulting from the use of electricity, machinery, equipment, vehicles and manual work;

- plan and others resulting from modifications and introductions of new technologies.

However, it is not only companies that need to comply with rules, but also their employees! It is up to the employees of these organizations to ensure their own health and integrity of their colleagues. To do so, they must comply with all regulations concerning the safety of mining work.

It is also the employee’s responsibility to immediately communicate to his superiors whenever he/she sees a situation he considers to be at risk or else see that a colleague is not performing the tasks as requested, so that this can become an imminent risk for everyone.

Safety equipment and measures

It is very important that professionals make use of Personal Protective Equipment (EPIs) that protect against possible damage caused by noise, dust, flyrocks and even landslides that may occur in mines.

Among the EPIs that stand out are:

- respiratory masks;

- ear plugs;

- goggles;

- welding masks and helmets;

- shoes and safety gloves.

- Steel toe boots

Three of the key major hazards — dust, vibration and fly rocks are discussed below.

DUST

Dust is present in all quarrying and opencast mining operations. While it is often considered to be more of an environmental issue, dust is a potential health risk and it is the nature of the dust that determines the associated risk.

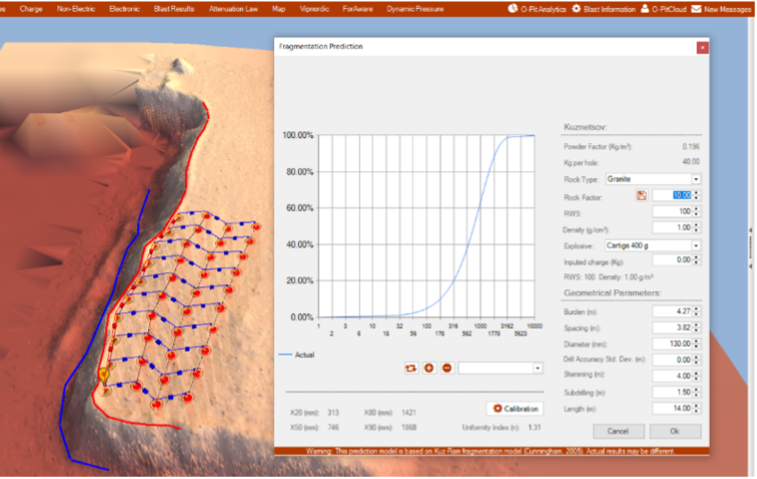

Controlling fragmentation is way to avoid producing dust.

VIBRATION

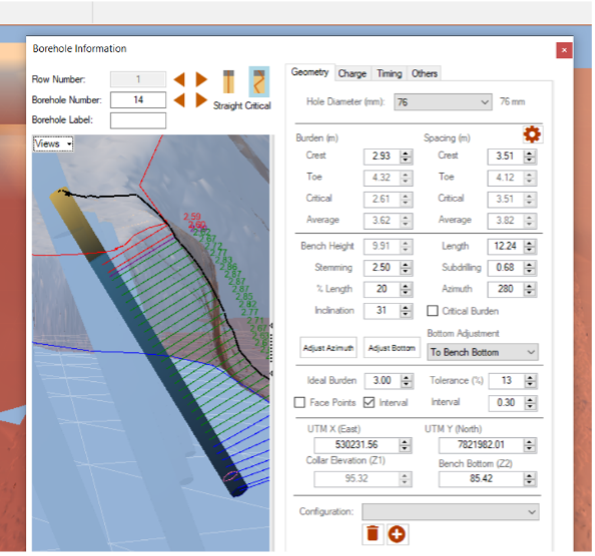

Vibration can cause several damage to the surrounding and the people working on the plant, the control of the vibration should be done in every blast. The measure of waves must be done in all blasts in order to control the spread of waves. The PPV can be reduce by applying correct timing in th tie up plan, by using decks or using the correct explosive when creating the blast plan.

FLY ROCKS

Flyrock, is a rock or rocks that are ejected from the blast site in a controlled explosion in mining operations. The term refers to rock that flies beyond the safety zone, causing injuries to people and damage to property. We can control the fly rocks using the correct steaming and controlling the calculation of the critical burden from the boreholes of the 1º row to the free face.This evaluation and control can also be done using a deviation probe like O-PitDev device.